Hot-dip galvanized steel structures. The material used for production is S235JR steel. The galvanizing process is carried out in accordance with PN-EN ISO 1461. The zinc used in the process is electrolytic zinc Z1 – 99.995% purity.

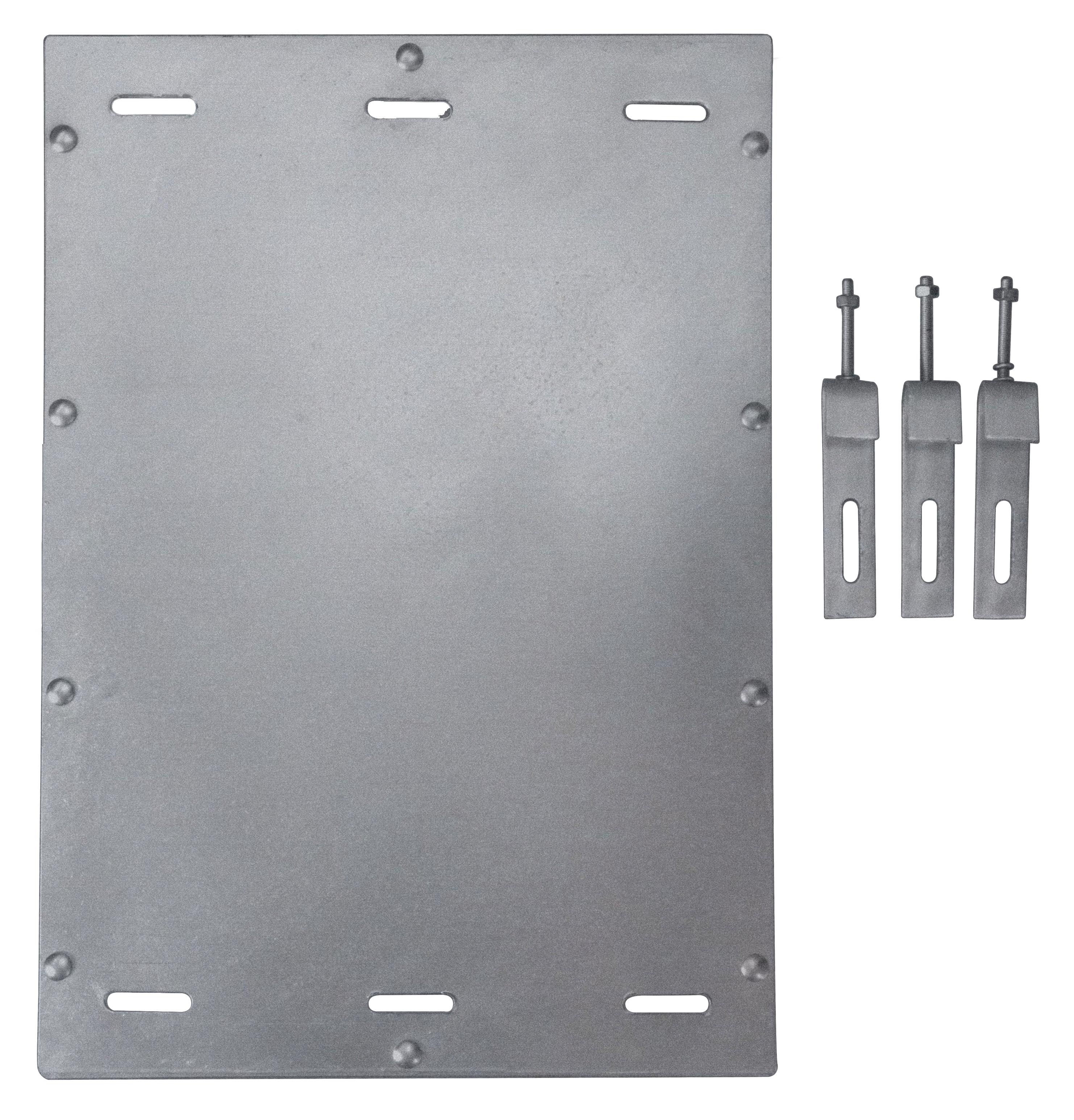

Side Mounting Structure

-

Material: S235JR Steel

Dimensions: Customized to fit the board size

Technology: Welding

Protection: Hot-dip galvanizing

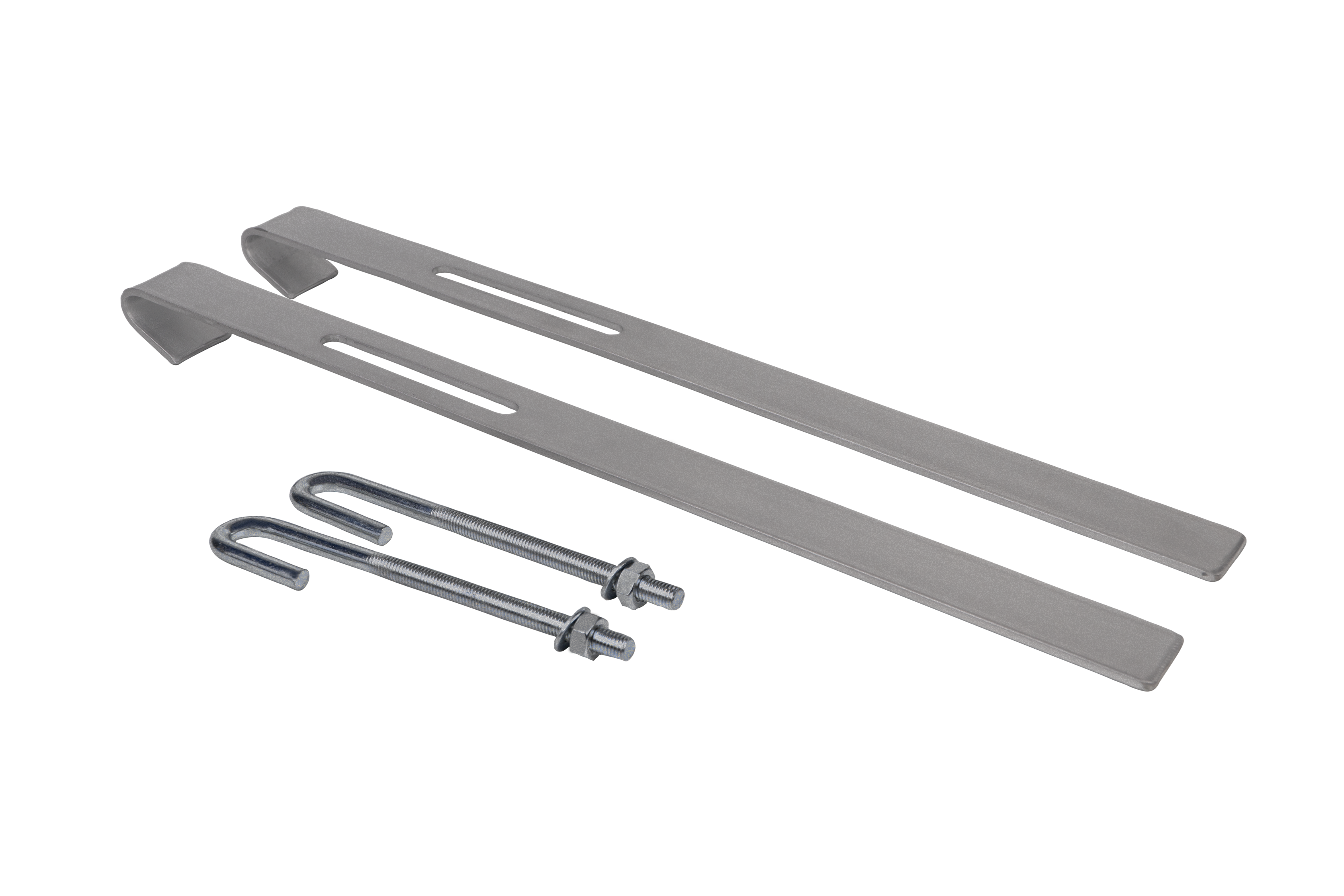

Centered Mounting Structure

-

Material: S235JR Steel

Dimensions: Customized to fit the board size

Technology: Welding

Protection: Hot-dip galvanizing

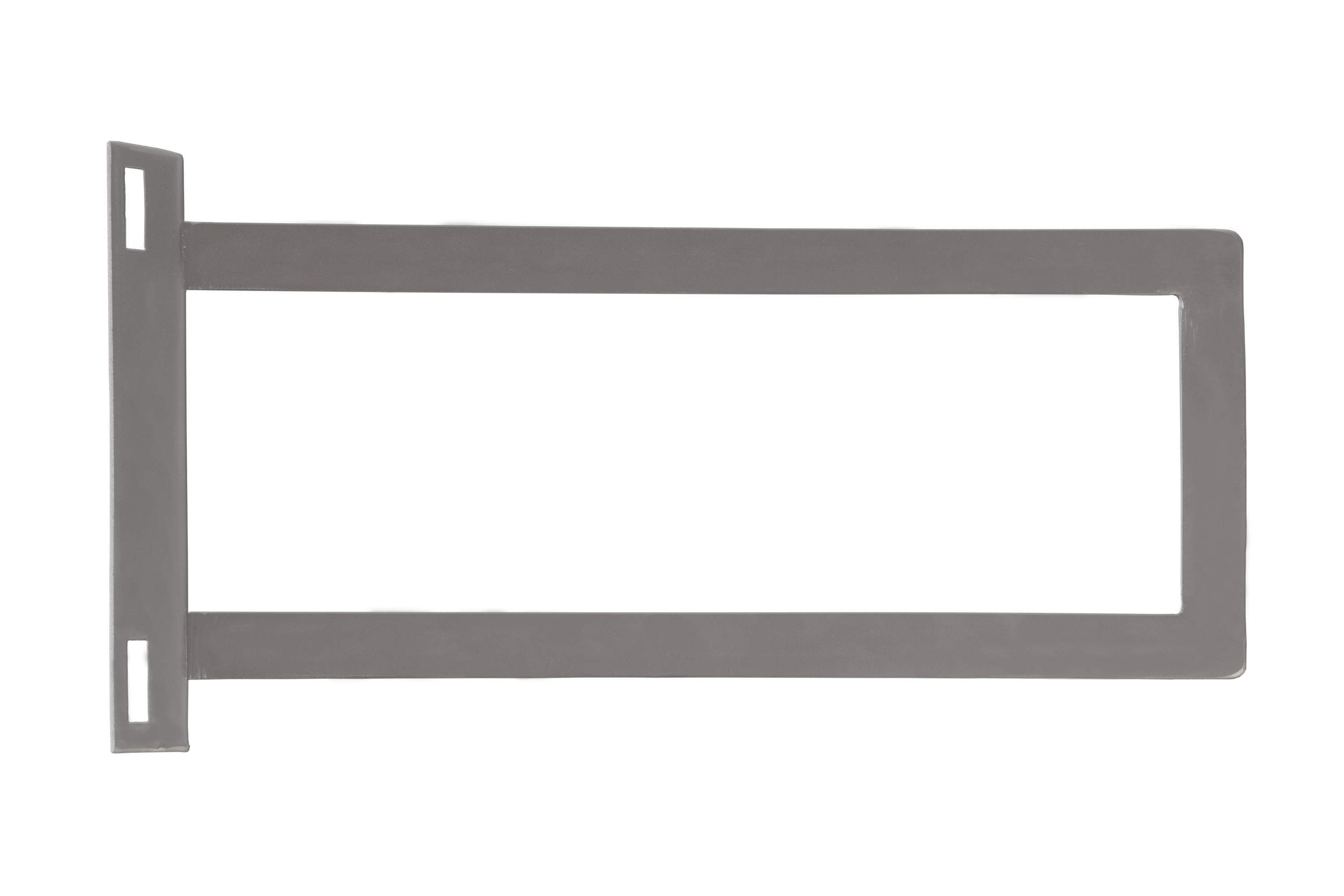

Small Centered Mounting Structure

-

Material: S235JR Steel

Dimensions: Customized to fit the board size

Technology: Welding

Protection: Hot-dip galvanizing

Mounting Structure for Phase and Track Boards

-

Material: S235JR Steel

Dimensions: Customized to fit the board size

Technology: Welding

Protection: Hot-dip galvanizing

Mounting Structure for Aviation Board

-

Material: S235JR Steel

Dimensions: Customized to fit the board size

Technology: Welding

Protection: Hot-dip galvanizing

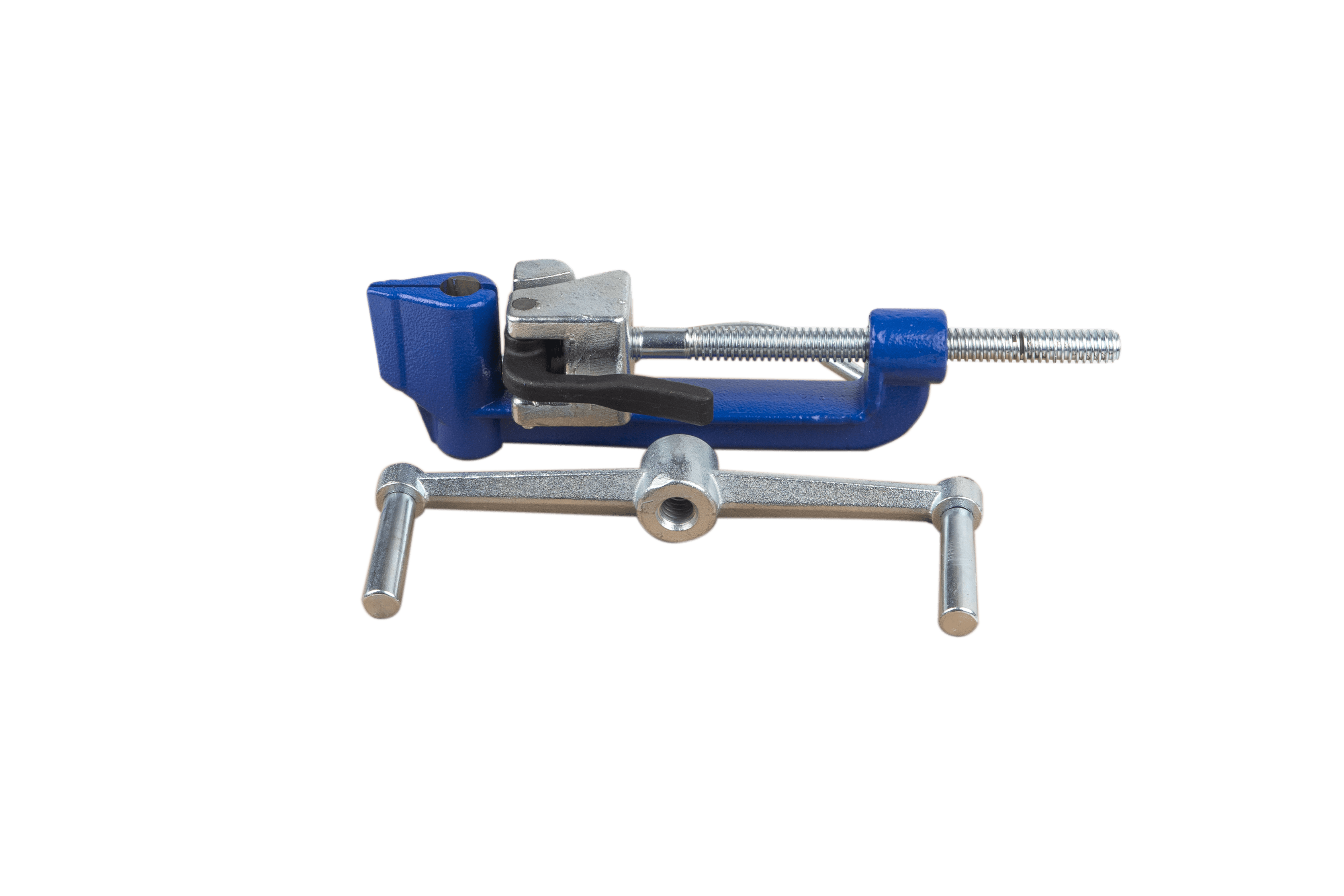

Screw Banding Tool for Tensioning and Cutting Steel Bands

-

The banding tool is designed for tensioning and cutting steel bands with a width ranging from 6.35 mm to 19.05 mm.

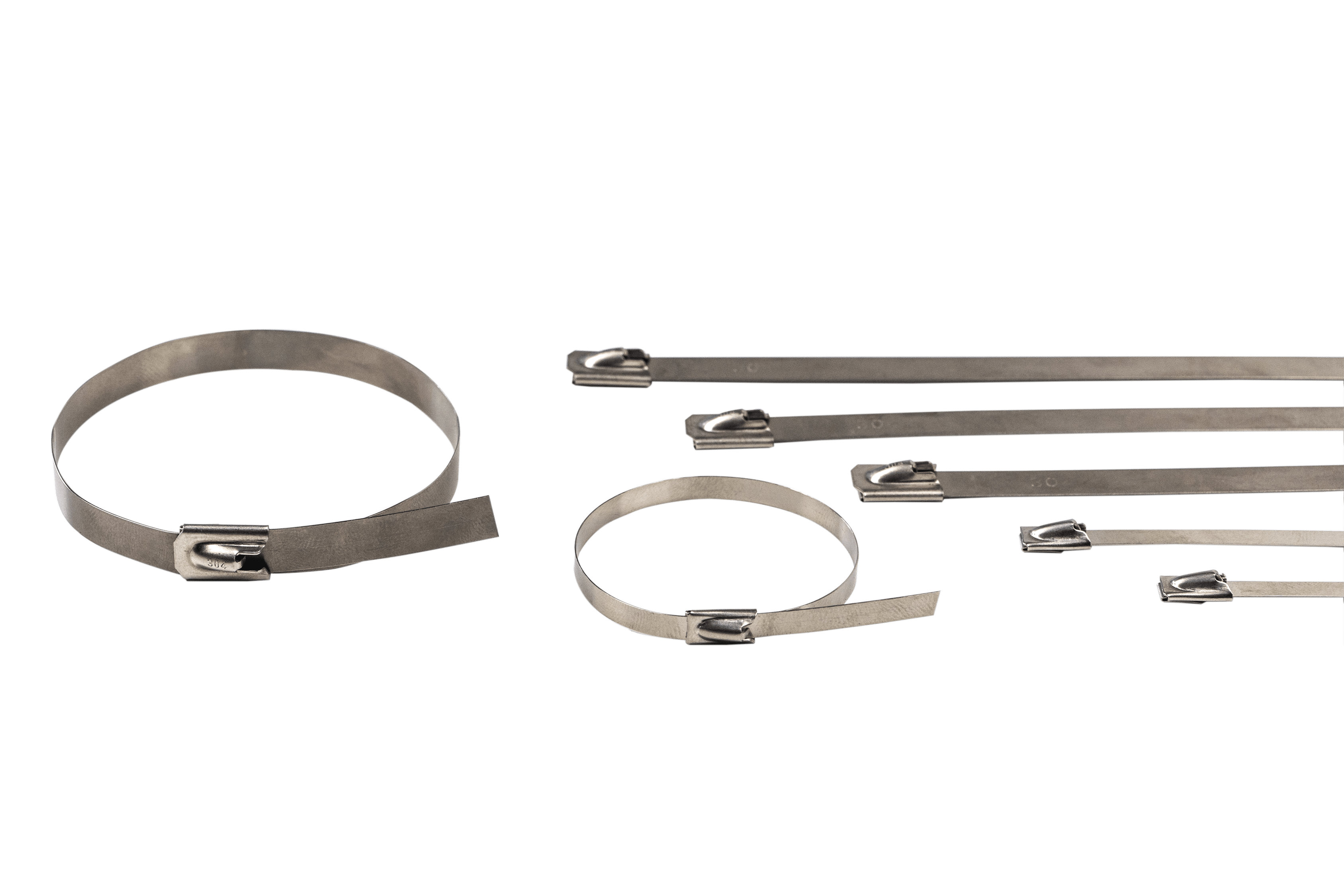

Stainless Steel Bands and Seals

-

Stainless steel bands and seals provide a durable and solid solution for mounting boards and structures in outdoor infrastructure.

Steel Band Clamping and Cutting Gun

-

The steel band clamping and cutting gun is a professional tool for quickly and conveniently tightening and cutting steel bands with a width ranging from 4.5 mm to 7.9 mm.

Information boards play a key role in identifying and managing energy infrastructure. However, to ensure these boards function effectively and last a long time, appropriate mounting structures are necessary. In this section, you will learn why the quality and durability of these structures matter, what types of mounting structures we offer, and how we can tailor our solutions to your individual needs.

What Are Mounting Structures for Energy Boards?

Mounting structures for energy boards are specially designed frameworks that allow for the installation and display of informational, control, or distribution boards related to energy infrastructure. They provide strong support and durability, which is essential for energy-related boards. Examples of mounting structures for energy boards include:

Centered

Side-mounted

Separate harness-type

Combined harness-type

Overhead control

Why Use Mounting Structures for Energy Boards?

Using mounting structures for energy boards offers many advantages:

1. Safety and Stability

Mounting structures for energy boards ensure not only stability but, more importantly, safety. Energy systems often operate under high pressure or are exposed to vibrations. Robust mounting structures protect the boards from damage or displacement, which is crucial for the reliable operation of energy infrastructure.

2. Weather Resistance

Energy boards are often installed outdoors and exposed to varying weather conditions. Mounting structures, especially those galvanized by hot-dip coating, are resistant to corrosion and rust, ensuring durability and reliability for years, regardless of weather conditions.

3. Minimizing the Risk of Failure

In energy infrastructure, any failure or downtime can be costly and impact energy supply. Mounting structures enhance system reliability, minimizing the risk of damage or power outages.

4. Customization for Specific Needs

There are many different types of energy boards, each requiring a different mounting structure. Our solutions allow customization according to specific needs, taking into account the type of board, its size, weight, and installation location.

Choosing mounting structures for energy boards is essential because they provide not only stability but also durability and safety for energy systems. Our hot-dip galvanized structures ensure strength and reliability, contributing to the efficient operation of energy infrastructure for many years.

Why Choose Our Mounting Structures for Energy Boards?

Contact Us

If you are interested in our mounting structures for energy boards, we invite you to contact us. Our team is ready to answer your questions, provide additional information, and assist you with your order. Want to learn more about how to place an order with us? Click the button below!

We are confident that our offer will meet your expectations, so we encourage you to explore our products and contact us if you have any questions or need additional information.

Order Free Samples

Choose the appropriate type of samples.

All you need to do is fill out a short form.

Contact Form

If you have questions you’d like answered, please use our contact form.